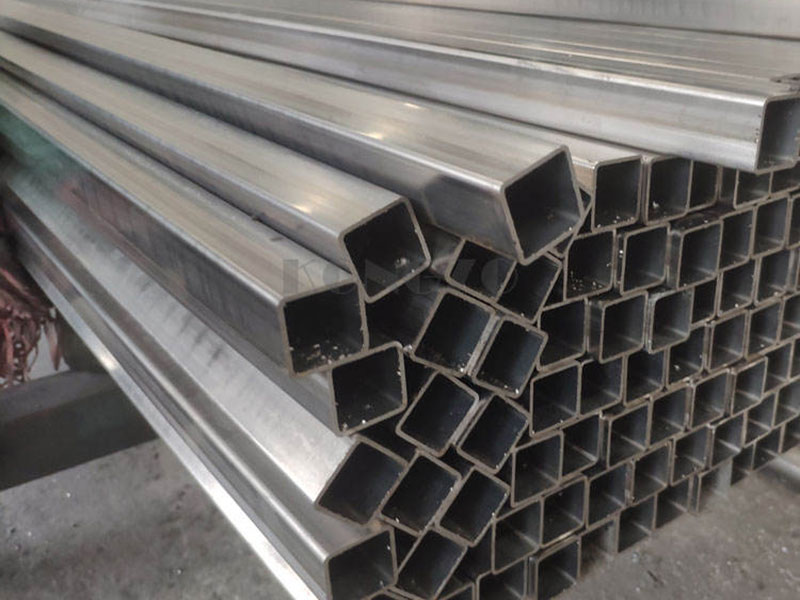

immaculatam ferro rectangulum tube

Specifications

| Specification | Crassitudo | 1-5mm |

| Latitudo | 10-200mm | |

| Longitudo | 5.8-6 Meters | |

| Standard | ASTM A53/ASTM A573/ASTM A283/ | |

| GB/T9711.1-1997 | ||

| DIN1629/4 DIN1629/3 | ||

| Materia | Q195,Q215,Q235B,Q345B,S235JR/S355JR/SS400 | |

| perfectus | Black/Galvanized/Coated/Oiled/Pictura, etc. | |

| Consuetudinem | Constructio, machinatio fabricatio, fabricatio ferri, firmamentum virtutis solaris | |

| Ferri structura machinalis, potentia machinalis, potentia plantae, machinae agriculturae et chemicae, parietes vitrei, automobile gb, nisl, etc. | ||

| Ars | ERW Welded | |

| stipare | Sacra mare dignum stipare, ferro ligatum | |

| Aut stipant sicut postulationem nativus | ||

| Patria Originale | China | |

| Principalis Market | Medius Oriens, Africa, Asia, America Meridionalis, Europa Orientalis | |

| MOQ | 5 Tons | |

| Productivity | 500 Tons/Month | |

| Trade & Payment | Trade: | EXW,FOB,CFR,CIF,DDP |

| Mercedem: | ≤ $8,000 T/T 100% advance | |

| > $8,000 T/T(30%+70%),30%T/T + 70%L/C | ||

| Praeterea Service | EXERCITATIO / Punching | |

| Lorem sectione magnitudine | ||

| Superficies nativus processus | ||

| Tendens / Welding / Decoiling | ||

| EXEMPLUM | APPLICANDIS |

| Steel Plate | Variae auriculae laesurae et aliae partes laesurae parvae, Navi aedificatio |

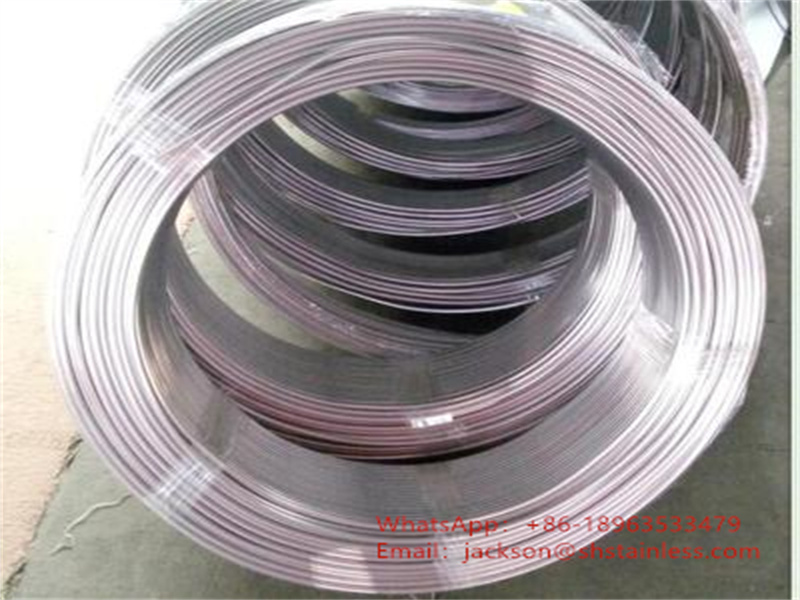

| Steel Coil | Late usus est in fabricando partium mechanicarum generalium.Maxime propter partes structurarum welding qualis est princeps requisita in constructione et ponte machinali. |

| Steel Strip | Vestibulum processus, idem quod ferrum coil |

| Ferro Pipe | Constructio, machinatio fabricatio, fabricatio ferri, fabricatio, potentiae solaris firmamentum, chalybea compages machinalis, potentia machinalis, potentia plantae, machinae agriculturae et chemicae, parietes vitrei, gb automobile; nisl, etc. |

| Steel Bar | Solebant instrumenta secanda, formas et instrumenta metientes |

Chemical Composition and Physical Properties for Stainless Stee

| Materia | ASTM A269 Chemical Composition % Max | ||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | NB | Nb | Ti | |

| TP304 | 0.08 | 2.00 | 0.041 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.0 | ^ | ^ | ^ . | ^ |

| TP304L | 0.035 | 2.00 | 0.041 | 0.030 | 1.00 | 18.0-20.0 | 8.0-12.0 | ^ | ^ | ^ | ^ |

| TP316 | 0.08 | 2.00 | 0.041 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP316L | 0.003 D | 2.00 | 0.041 | 0.030 | 1.00 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP321 | 0.08 | 2.00 | 0.041 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | ^ | ^ | ^ | 5C -0.70 |

| TP347 | 0.08 | 2.00 | 0.041 | 0.030 | 1.00 | 17.0-19.0 | 9.0-12.0 | 10C -1.10 | ^ | ||

| Materia | Calor treatment | Temperies F (C) Min. | duritia | |

| Brinell | Rockwell | |||

| TP304 | Solutio | 1900 (1040) | 192HBW/200HV | 90HRB |

| TP304L | Solutio | 1900 (1040) | 192HBW/200HV | 90HRB |

| TP316 | Solutio | 1900(1040) | 192HBW/200HV | 90HRB |

| TP316L | Solutio | 1900(1040) | 192HBW/200HV | 90HRB |

| TP321 | Solutio | 1900(1040) F | 192HBW/200HV | 90HRB |

| TP347 | Solutio | 1900(1040) | 192HBW/200HV | 90HRB |

| OD, inch | OD Tolerantia inch(mm) | WT tolerantia % | Longitudo Tolernace pollicis (mm) | |

| + | - | |||

| ≤ 1/2 | ± 0.005 ( 0.13 ) | ± 15 | 1 / 8 ( 3.2 ) | 0 |

| > 1 / 2 ~ 1 / 2 | ± 0.005(0.13) | ± 10 | 1 / 8 (3.2) | 0 |

| > 1 1 / 2 ~< 3 1 / 2 | ± 0.010(0.25) | ± 10 | 3/16 (4.8) | 0 |

| > 3 1 / 2 ~< 5 1 / 2 | ± 0.015(0.38) | ± 10 | 3/16 (4.8) | 0 |

| > 5 1 / 2 ~< 8 | ± 0.030(0.76) | ± 10 | 3/16 (4.8) | 0 |

| 8~< 12 | ± 0.040(1.01) | ± 10 | 3/16 (4.8) | 0 |

| 12~< 14 | ± 0.050(1.26) | ± 10 | 3/16 (4.8) | 0 |

Dimensiones Nominales Pipe

Factoy photos

Epistulam tuam hic scribe et mitte nobis