1000Mtr / roll SS316L Steel Coiled Tubing

Carus mos, gaudeo tibi nostrum premium inactum ferro incutere 316L Classis Seamless Coiled Tubing.Facientes sumus tortum Tubing fabrica cum productio primae classis et probatio instrumenti.Proferre possumus 316L TUBING plexu variarum specificationum, OD cum 3/4in, 1in, 1 1/2in, 1 3/4in, 2in, 2 3/8in, etc. Specificationes nativus esse possunt.Nostra producta parere cum ASTM A269, ASTM A789, ASTM B704, ASTM A370, ASTM A450, ASTM E426 aliaque signa.Per annos incepta cum KNPC, KOC, KOC nationalibus olei societatibus adiunximus et producta nostra toto orbe bene vendiderunt.Productum qualitas a clientibus summis laudibus est.Inconsutilem iuncta et iuncta Tubing possumus producere.Nonnulli gyros Tubingae gyros sunt 100-30,000 ft longitudinis et in putei aquae profundae adhibentur.Si opus est, grata quaerendum, opus expectamus apud te!

PHYSICA POTESTAS

Vires cede: ≥40,000 psi

Robur distrahens: ≥70,000 psi

Maxime duritia: 200HV

CHEMICAL COMPOSITION-%

Carbon ≤0.030

Manganum ≤2.00

Phosphorus ≤0.045

Sulphur ≤0.030

Pii ≤0.75

Chromium 16.0-18.0

Nickel 10.0-14.0

Molybdenum 2.00-3.00

Tubus Lond Corpus:

Cede & Tensile Minimums calculata in Muro certa.

Hydrostatic Test Pressura:

Totus chordarum tubingarum amplexus completus erit pressionis hydrostaticae ante naviculas probatae. Pressura hydrostatica minor 90% of theoricae rupti vires cedit vel 17,500 psi vel 120700 kpa (nisi specialiter inter emptorem et opificem convenerit).

Internum cede: Internus Impetus est

causam cedere usura Minimum cede

Fortitudo et minimum Wall Crassitudo.

Maxima Pressio Operationis munus est conditionis tubi et ab utentis determinatur.

Torque Pretio Calculated Usura minimum Wall Crassitudo et Minimum Fortitudo cede.

Aliae magnitudinis/muri crassitudines in petitione praesto sunt.

Supra data ad novas Tubingas ad vires minimas definitas est.

Compositio chemica tabula materiae ferro immaculatae

| A312 GRADIBUS | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

| TP304 | S30400 | 0.08 | 2 | 0.041 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304L | S30403 | 0.035 | 2 | 0.041 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| TP304H | S30409 | 0.04-0.10 | 2 | 0.041 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304N | S30451 | 0.08 | 2 | 0.041 | 0.03 | 1 | 18.0-20.0 | 8.0-18.0 | 0.10-0.16 | |||

| TP304LN | S30453 | 0.035 | 2 | 0.041 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | 0.10-0.16 | |||

| TP309S | S30908 | 0.08 | 2 | 0.041 | 0.03 | 1 | 22.0-24.0 | 12.0-15.0 | 0.75 | |||

| TP309H | S30909 | 0.04-0.10 | 2 | 0.041 | 0.03 | 1 | 22.0-24.0 | 12.0-15.0 | ||||

| TP309Cb | S30940 | 0.08 | 2 | 0.041 | 0.03 | 1 | 22.0-24.0 | 12.0-16.0 | 0.75 | 10xC min | ||

| 1.10 max | ||||||||||||

| TP309HCb | S30941 | 0.04-0.10 | 2 | 0.041 | 0.03 | 1 | 22.0-24.0 | 12.0-16.0 | 0.75 | 10xC min | ||

| 1.10 max | ||||||||||||

| TP310S | S3108 | 0.08 | 2 | 0.041 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | 0.75 | |||

| TP310H | S3109 | 0.04-0.10 | 2 | 0.041 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | ||||

| TP310Cb | S31040 | 0.08 | 2 | 0.041 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | 0.75 | 10xC min | ||

| 1.10 max | ||||||||||||

| TP310HCb | S31041 | 0.04-0.10 | 2 | 0.041 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | 0.75 | 10xC min | ||

| 1.10 max | ||||||||||||

| TP316 | S3160 | 0.08 | 2 | 0.041 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316L | S31603 | 0.035 | 2 | 0.041 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |||

| TP316H | S31609 | 0.04-0.10 | 2 | 0.041 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316Ti | S31635 | 0.08 | 2 | 0.041 | 0.03 | 0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 5x | 0.1 | |

| (CN) | ||||||||||||

| -0.7 | ||||||||||||

| TP316N | S31651 | 0.08 | 2 | 0.041 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10-0.16 | ||

| TP316LN | S31653 | 0.035 | 2 | 0.041 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | 0.10-0.16 | ||

| TP317 | S3170 | 0.08 | 2 | 0.041 | 0.03 | 1 | 18.0-20.0 | 10.0-14.0 | 3.0-4.0 | |||

| TP317L | S31703 | 0.035 | 2 | 0.041 | 0.03 | 1 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | |||

| TP321 | S3210 | 0.08 | 2 | 0.041 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 0.1 | |||

| TP321H | S32109 | 0.04-0.10 | 2 | 0.041 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 0.1 | |||

| TP347 | S3470 | 0.08 | 2 | 0.041 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | ||||

| TP347H | S34709 | 0.04-0.10 | 2 | 0.041 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | ||||

| TP347LN | S34751 | 0.05-0.02 | 2 | 0.041 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | 0.20- | 0.06-0.10 | ||

| 50 | ||||||||||||

| TP348 | S3480 | 0.08 | 2 | 0.041 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | ||||

| TP348H | S34809 | 0.04-0.10 | 2 | 0.041 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | ||||

Coiled Tubing & Coiled line pipe

Product Name:Stainless Steel Coiled Tubing and Coiled line pipe

Product genera et species

OD: 19.05mm~88.9mm

WT :1.91mm-7.62mm

Length: Max.8000m

Maximum pondus unius reel: 30t (exclusa reel)

Maximum extra diametrum tympani: 3.40m

Specification: ASTM A269、A213,ASTM A789, ASTM B704, ASTM A370, ASTM A450, APIRP5 C7、JISG4305、JIS G3463、DIN2469、API Spec 5ST,API Spec.5LCP

Ferro gradus: API Spec.5ST CT70-CT110、API Spec.5LCP X52C~X90C,

316L、304L、Inconel625、Incoloy825、UNS N04400 UNS S32205/S31803(ASTM A240)、S2507/ UNS S32750

Vires cede: tubing 483mpa-758mpa amplexus (70ksi-110ksi), fistula linea spiralis 359mpa-621mpa (52ksi-90ksi)

Nota: speciales specificationes, materiae et productorum longitudo potest nativus secundum exigentias mos

Magnam experientiam habemus in e duplo, nickel mixturam et immaculatam ferro gradus ad industriam et ad specialia requisita, in gyros Tubing producere.Tubing amplexus in longitudinibus a 100 pedibus (30 metris) ad 30,000 pedes (10,000 metrorum praesto est). Tubing in IPPC certificata ligna vel metalla concutiri potest, usorum specificationibus.Applicationes comprehendunt Tubing capillares pro injectione chemica, nuda et encapsulata linea hydraulica potestate valvulae subseae tuta, chordae velocitatis, chordae opus, et tubus umbilicus ferreus.

EMHK fabricat ferrum incorruptum medicatum coil Tubing et metrice inactum ferro Tubing.Oleum EXERCITATIO in Platform, Oleum bene, Heatwell adhiberi potest. Una optimae qualitatis amplissimae ferri intemeratae politi medici coilum Tubingae et metricae ferro inaculato Tubingae praebet.Coilum medicatum Tubingae ex variis materiis conficitur.Coil Tubing medici inactum ferro expolitum sunt fistulae ferreae immaculatae politae quae in gyris in apparatibus medicis adhibentur.

316LSeamless chalybs immaculata tubum plexum/pipe, Materia: 304 / 304L / 316 / 316L / Duplex 2205 / Monel 400 / Inconel 625 / Inconel 825 , Superface: Tam intus et extra splendida sunt annata, munda et compaginaliter discursum sine ultrices. size:1/8″*0.025″,1/4″*0.049″,3/8″*0.049″,1/2″*0.049″,1/2″*0.065″, 3/4″*0.075″; 1″*0.075,1 1/2″*0.083″,2″*0.109″,2 3/8*0.109″,2 5/8*0.118″,3 1/2*0.156″,etc.

Capillares tubi Capillares Immaculatam Moles et Pressura Rating:

| Magnitudo ferri Capillaris Tubing

| ||||

| ITEM | Gradus | Magnitudo | Longitudo | Pressura (Mpa) |

| 1 | 316L 304L 304 625 825 2205 2507 | 1/8″×0.025″ | 3200 | 80

|

| 2 | 316L 304L 304 625 825 2205 2507 | 1/8″×0.035″ | 3200 | 100

|

| 3 | 316L 304L 304 625 825 2205 2507 | 1/4″×0.035″ | 2000 | 100

|

| 4 | 316L 304L 304 625 825 2205 2507 | 1/4″×0.049″ | 2000 | 100

|

| 5 | 316L 304L 304 625 825 2205 2507 | 3/8″×0.035″ | 1500 | 80

|

| 6 | 316L 304L 304 625 825 2205 2507 | 3/8″×0.049″ | 1500 | 100

|

| 7 | 316L 304L 304 625 825 2205 2507 | 1/2″×0.049″ | 1000 | 80

|

| 8 | 316L 304L 304 625 825 2205 2507 | 1/2″×0.065″ | 1000 | 100

|

| 9 | 316L 304L 304 625 825 2205 2507 | φ3mm×0.7mm | 3200 | 80

|

| 10 | 316L 304L 304 625 825 2205 2507 | φ3mm×0.9mm | 3200 | 100

|

| 11 | 316L 304L 304 625 825 2205 2507 | φ4mm×0.9mm | 3000 | 100

|

| 12 | 316L 304L 304 625 825 2205 2507 | φ4mm×1.1mm | 3000 | 100

|

| 13 | 316L 304L 304 625 825 2205 2507 | φ6mm×0.9mm | 2000 | 100

|

| 14 | 316L 304L 304 625 825 2205 2507 | φ6mm×1.1mm | 2000 | 100

|

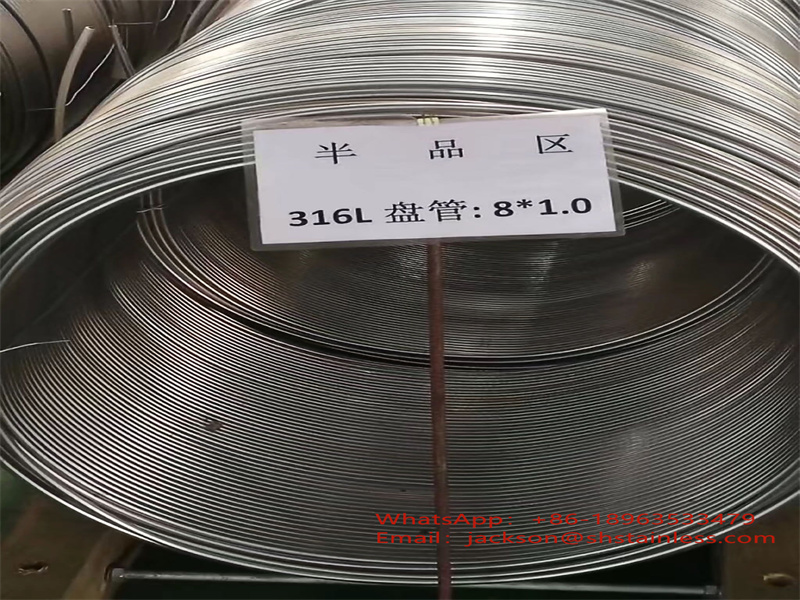

| 15 | 316L 304L 304 625 825 2205 2507 | φ8mm×1mm | 1800 | 80

|

| 16 | 316L 304L 304 625 825 2205 2507 | φ8mm×1.2mm | 1800 | 100

|

| 17 | 316L 304L 304 625 825 2205 2507 | φ10mm×1mm | 1500 | 70

|

| 18 | 316L 304L 304 625 825 2205 2507 | φ10mm×1.2mm | 1500 | 70

|

| 19 | 316L 304L 304 625 825 2205 2507 | φ10mm×2mm | 500 | 100

|

| 20 | 316L 304L 304 625 825 2205 2507 | φ12mm×1.5mm | 500 | 80 |

| Product Name | Stainless Steel Coiled Tubing-Steel Coiled tube/pipe-Seamless capillaribus Tubing-Rolled tubing/pipe-Steel praecisione tubing-Steel Continuus Oil pipe, Heat well Oil long bending pipe | ||

| Materia | 304,316L,Duplex 2205, Monel 400, Inconel 825, Inconel 625, UNS N04400、 UNS S32205/S31803(ASTM A240)、S2507/ UNS S32750, API Spec.5ST CT70-CT110、API Spec.5LCP X52C~X90C | ||

| Crassitudo | 0.1-7.62mm, | ||

| OD | 0.3-88.9mm | ||

| Superficiem Conclusio | Annealed et Bright,Clean intus et extra, nullo lappa, utrinque inconsutilem. | ||

| Standard | ASTM A269、A213,ASTM A789, ASTM B704, ASTM A370, ASTM A450, APIRP5 C7、JISG4305、JIS G3463、DIN2469、JIS G4305 / GB / T 12770-2002GB / T12771-2002, API Spec 5ST,API Spec.5LCP | ||

| Longitudo | Quisque volumine est 200-1000m,or sicut per huius petitionem | ||

| Applicationem | Oleum EXERCITATIO rostris, Oleum bene, Heatwell.Late etiam usus est in oleum et gasi naturales pascendi, cibi industriae, armorum potus, apparatus cervisiae, ratio caloris commutatoris, systematis lac/aquarum, instrumenti medici, energiae solaris, instrumenti medici, aviationis, aerospace, communicationis, petrolei et aliarum industriarum; | ||

| stipare | Velum bullae, tympanum ferreum, grabatum ferreum, vel arca lignea.Secundum petitiones tuas | ||